Health, Safety & Environment

Reliance’s endeavour to create a culture of safety, health and environment saw a new light with the implementation of Change Agents for Safety, Health and workplace Environment (CASHe). This project has garnered enough strength to make safety and health a priority in the workplace and improved occupational safety and health significantly. Reliance’s HSE Management System has established company-wide safety management objectives and processes for improving operational discipline and evolving inherent safety measures for plant operation. In addition, the Central HSE audit programme — a critical component of the HSE governance process — is designed to ensure that the HSE Management Standards are implemented and best practices are followed and shared across the Reliance Group.

Reliance is also committed to ensuring environmentally sustainable and responsible operations to achieve highest standards of excellence. Our manufacturing divisions have not only instituted internationally accepted Environmental Management System based on ISO-14001, but the major sites are also integrated with Quality Management and Occupational Health & Safety Management Systems.

For instance, we have set up Occupational Health Centres for emergency and curative services and are also focusing on emotional well-being through our "Work-Life Project". We continuously standardise and upgrade systems to reach our target of zero injuries and incidents. We also remain deeply committed to the cause of environmental protection and have rainwater harvesting programmes and three-tier environmental audits in place, among other systems.

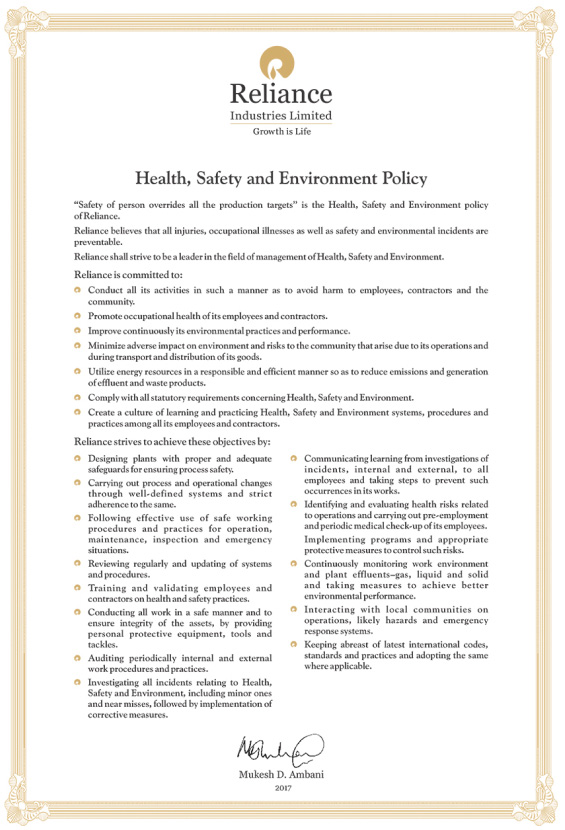

Health, Safety & Environment Policy

Environmental Stewardship

The RIL HSE vision embraces the concept of sustainable development focused on environmental sustainability. We recognize that sustainable business advantage occurs when we understand and address environmental issues in our operations including development of products and their delivery. RIL sites aspire to increase energy efficiency of production processes, apply advanced technology to produce less waste and demand less energy, reduce and eliminate flaring and venting of feed and product gases, including volatile organic compounds. These are the first steps toward environmental sustainability, focusing on operating processes that minimize resource use and environmental waste.

Our manufacturing facilities follow a set of principles that guides our commitment to environmental stewardship in everything that we do. Highlights of these principles include:

- We comply with all applicable laws and regulations, but also seek to reduce and, where possible, eliminate hazardous waste through source reduction and recycling.

- We continually work to minimize environmental impact through safe technologies, facility design and operating procedures.

- We conserve energy and work to improve the manufacturing efficiency of the products we manufacture and of our own operations.

- We conduct regular training to ensure knowledge of updated laws and regulations, pollution-prevention and waste-minimization practices, and technological developments.

- We periodically audit our operations to confirm compliance with these principles and local laws.

Reliance adopts a broad approach to reducing environmental footprint across all our businesses. This covers clean air and water, preventing soil contamination, preserving biodiversity, optimal utilization of resources and digitization. Aided by technology and science, Reliance tracks, streamlines and manages GHG emissions across its manufacturing units. Reliance’s state-of-the-art facilities and the ability to deploy leading technologies at each site ensures sustainable growth for the company. Retrofit investments across manufacturing units help reduce the environmental impact and energy consumption. Real-time monitoring of stack emissions through continuous emission and effluent monitoring systems enable the company to monitor emissions.

All the manufacturing entities of Reliance have the applicable approvals in the form of environmental clearances, consents, authorizations and any other applicable regulatory requirements. In order to meet all the regulatory requirements the manufacturing entities at Reliance report their environmental performance as per the laid down norms like emission and effluent quality monitoring in various reports, environment statements, six monthly compliance reports, as applicable, various returns on hazardous waste, e-waste, bio-medical wastes, ash management, audit reports.

Six Monthly Compliance Reports

Bio Medical Waste

| Locations | Biomedical Wastes Categories | Quantity (kg) |

|---|---|---|

| Hazira Manufacturing Division (DOT Centre) | Yellow | 3.82 |

| Red | 13.80 | |

| White | 2.38 | |

| Blue | 3.59 |

Manufacturing sites also implement, are accredited against the ISO standards and are certified with a third-party audit. The Reliance Operating Management System is leveraged to develop and implement the Environment Management System across the group.

The purpose of these audits is to evaluate environmental regulatory compliance and the overall environmental management practices of each plant. These assessments encourage plant operating managers to look beyond basic compliance and explore ways to implement innovative and productive environmental management practices.

Emission hotspot analysis along with mandatory audits, data monitoring, and verification across sites ensure baselining the impact of our business. Water is a critical resource for Reliance operations. Reliance deploys state-of-the-art technologies to reduce dependency on freshwater through increased recycling and reduced external discharge. Treated effluents are reused in the cooling towers, horticulture activities and firewater networks. Reliance is a firm believer of the principles of circular economy led by 3Rs- Reduce, Reuse, Recycle. Recycling hazardous waste for use as alternate fuels and raw material for cement industries, metal recovery, or regeneration is adopted for reducing the impacts of waste.

Global requirements are pushing businesses to accelerate transition to low-carbon economy and grow responsibly and meet investor expectations. The technological disruptions and growing consumer preference for environment friendly products is an opportunity for the company. Reliance as an organisation is prepared with its strategy to address this shifting customer demand.

Reliance has strengthened its internal governance mechanism to minimise and mitigate risk, as applicable, as operations transition to low carbon operations. The company is increasing R&D investments to accelerate innovation for carbon reduction while improving operational efficiencies.

The objective of environmental and sustainability stewardship is to have an oversight that the sites are meeting the consent terms and meeting the environmental regulations and going beyond compliance. This approach brings together cross functional teams to ensure that proactive environmental management practices such as implementing aggressive pollution‐prevention programs are in place.

This ensures comprehensive environment‐related performance measures that are in place and encourage developing green products and process technologies and provides opportunities to strengthen RIL’s distinctive competence in terms of operations objectives such as highest quality, lowest cost, best dependability, and greatest flexibility.